BACO Advanced Disinfection System

What is Baco?

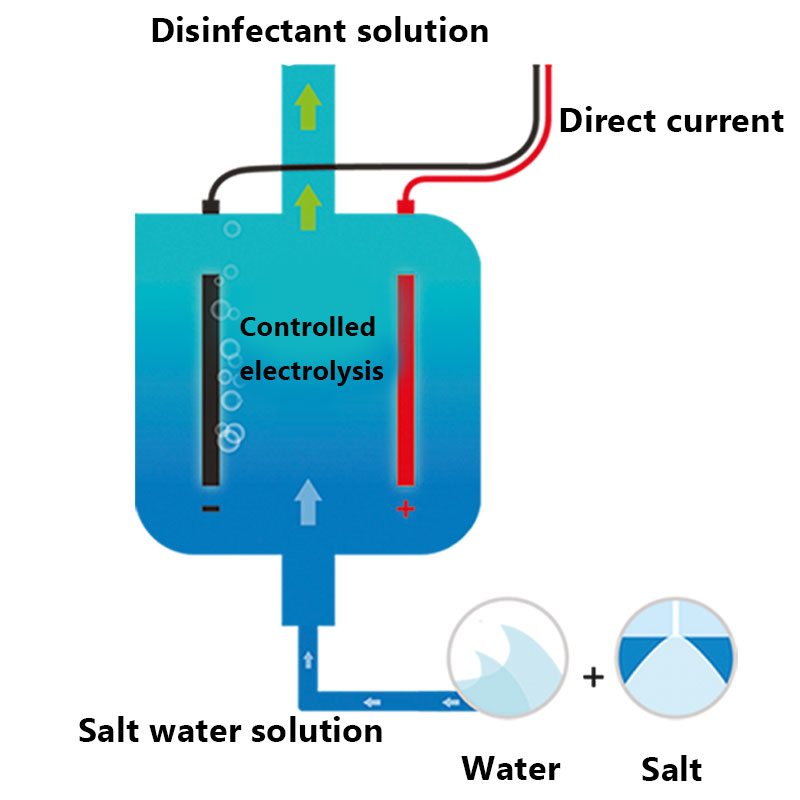

Baco is the brand name of advanced water treatment systems by controlled electrolysis of NaCl solution produced by Behinab Zenderood Company.

What is Baco disinfectant solution?

The solution obtained from the controlled electrolysis of water and NaCl solution by Baco system is called Baco disinfectant solution. This solution is a combination of several effective oxidants including sodium hypochlorite, hydrogen peroxide, chlorine dioxide, ozone and hypochlorous acid.

What are the uses of Baco system?

- Wastewater treatment effluent and industrial water in cooling towers and desalination plants

- Disinfection of drinking and sanitary water, water in swimming pools and water parks

- Disinfection and sterilization of surfaces, clothing, fruits and vegetables

What are the advantages of using Baco disinfectant over other disinfectants?

- Do not change the taste and smell of water

- High shelf life

- Remove unpleasant taste and smell from water

- Do not add toxic substances to water

- High safety during production, maintenance and consumption

- Reduce disinfectant consumption due to higher power

- High disinfection speed and need less contact time

- Available, cheap and safe raw materials (NaCl)

- Removal of biofilm from tank walls and water transmission and distribution pipes

- Leaving stable free residual active chlorine in water distribution networks

- No need for special equipment and safety training to disinfect with this solution

- How is the operation of Baco systems? All the necessary processes are done automatically by Baco system and its operator needs to deplete the salt in the salt storage tank, daily inspection and periodic service.

- Does the Baco system have sewage or by-products during production? No, all inputs to this system have been disinfectant solution and is useable.

- Where are Baco systems produced?All stages of design and construction of these systems are performed by the specialists of Behinab Zenderood Company.

- What are the raw materials required and the amount of it to produce Baco solution? The consumables of Baco system are only salt and electricity and the water entering this system returns to the network as a disinfectant solution. These systems consume 4 to 5 grams of NaCl and 4 to 5 watts of electricity to produce per gram of disinfectant (equivalent to one gram of active chlorine).

- What is the process of producing disinfectant solution by NaCl electrolysis method in Baco system? The water entering the system enters the resin softners after passing through the first filter, which is usually sand or polypropylene cartridge filter. After softening, the produced soft water is mixed with salt and the salt water solution is produced automatically with the required concentration. The resulting solution enters the electrolyzer and by applying direct current, electrolysis is performed. The solution obtained by electrolysis, which is Baco disinfectant solution, is stored in the tank and finally the disinfectant solution stored in the tank is injected into the place of consumption using a pump. In the process of electrolysis of salt water, hydrogen gas is produced which is safely directed from the storage tank to the open space outside the installation site.

- What is the instrumentation and control equipment of Baco system? All settings related to the system can be done through the user interface display. Intelligent control of the system is done by PLC and it is possible to update and apply changes. This system is equipped with various control sensors including temperature, amperage and voltage sensors and liquid level sensors in tanks.

- Where should spare parts be provided if needed? ? All parts used in this system are of high quality and can be easily accessed and supplied in the domestic market.

- How to manage error in Baco system? Baco system has an intelligent safe stop system. When an error occurs, the siren sounds and the display shows the reasons for the error, and the user can troubleshoot and fix the error according to the error management guide.